Our Process

ATTENTIVE, CONSCIENTIOUS, AND PERSISTENT PARTNERS

Whether working with a two-person startup or a Fortune 500 firm, Humanfactors takes the same comprehensive approach to problem solving. Below are the research and development activities executed during a typical project. Sometimes, clients need only select phases within the process to validate an idea.

Identify the Problem

User Research

Despite starting from a position of clarity, the problem we’re tasked with solving often evolves once we begin researching users. That diabetic infusion set may need a facelift, but conducting user focus groups may point to too many operational steps, or difficulties cleaning, or an uncomfortable injection angle.

Humanfactors sometimes begins a project with a valuable trove of a client’s own research - we’ll work with them to identify, parse, and leverage their existing market research, which may include VOC (voice of customer) documents, sales analyses of demographics, or even user studies. All of this research forms the foundation of a marketing requirements document, which will guide the development of product specifications in subsequent development phases.

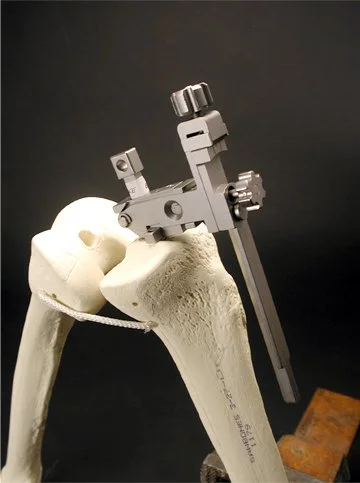

User Observation

We design products for healthcare consumers, and also for medical practitioners. Developing surgical instrumentation, for example, benefits from surgical observation, which means spending time in the operating room, sometimes the cadaver lab, observing multiple surgeries, speaking with scrub techs, engaging surgeons about each procedural step. What started out as a clumsy surgical instrument issue may, through surgeon conversation and observation, be revealed to be a procedural problem, or even a flawed implant design. There’s no more effective means of understanding the full nature of the problem we’re trying to solve.

Market Research

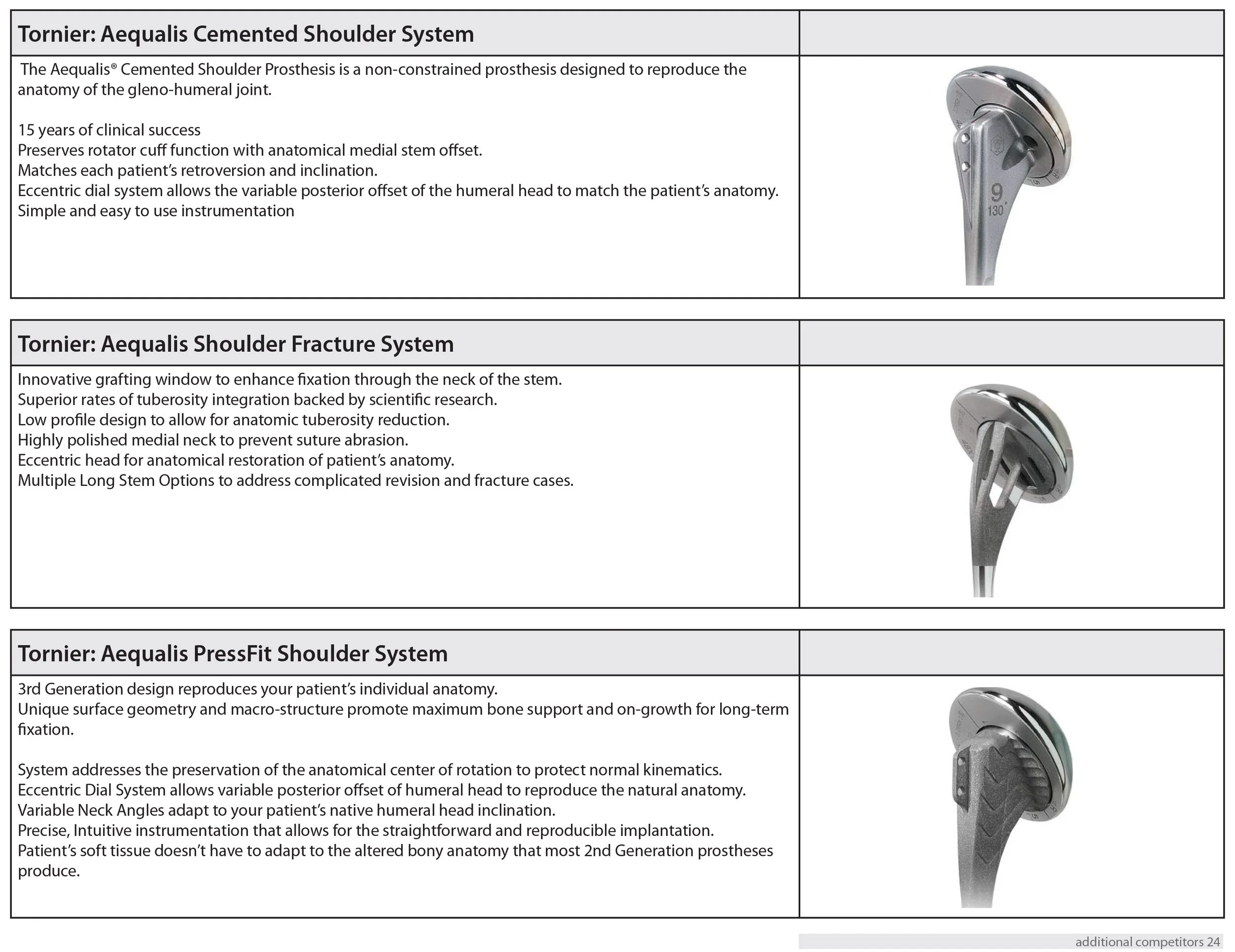

Market Landscape Investigation

Humanfactors researches, compiles, and evaluates competitive devices - current or future - against a broad scope of criteria including: ergonomics, functionality, durability, cleanability, intuitiveness, material choice, device feedback, manufacturing technique & strategy, and other relevant measures. It may be useful to employ a quantifiable analytical tool, such as a SWOT matrix, to better identify risk, opportunity, and emerging trends within the market space. To the extent they’re available, we try to obtain as many competitive devices as possible, as physical inspection is often the optimal method of evaluation.

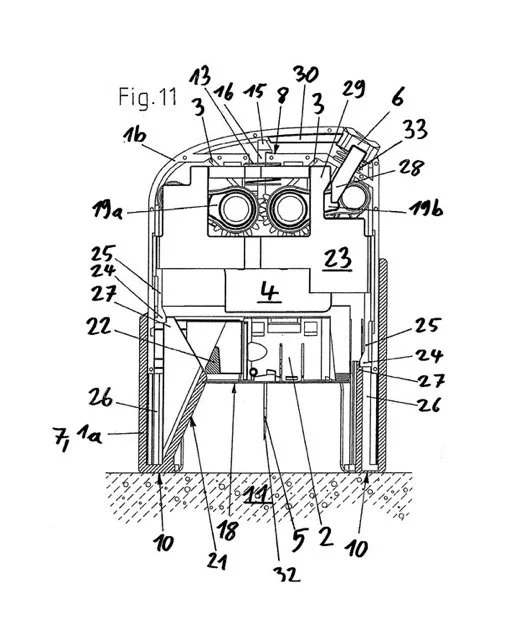

Patent Analysis

Humanfactors performs an investigation into, and evaluation of, the patent landscape of the client’s product landscape. This information enables us: 1) to identify potential products and features that cannot be infringed upon, 2) to determine, if necessary, how to design around existing patents to avoid infringement, and 3) to identify areas for developing and protecting new intellectual property.

Product Specification

By this stage, Humanfactors will have developed a comprehensive market requirements document serving as the foundation of the product specification, detailing the functionality of what the product must embody and deliver. For each of the user needs identified in the market requirements document - safety features, ergonomic, storage preferences, etc. - there will be a physical corollary and specification. The product specification will guide concept development.

Concept Development

Design: Concept Sketching

Using the Marketing Requirements Document and Product Spec as a development guide, Humanfactors - through sketching, modeling, and other media - explores aesthetics, ergonomics, features, user scenarios and performance, intuitiveness, and other product concepts from a full spectrum of user, engineering, and marketing perspectives. Intensive evaluation and refinements yield a device conceptualization - a hybrid of various ideas, features, and technologies - that will define the ensuing phases of development.

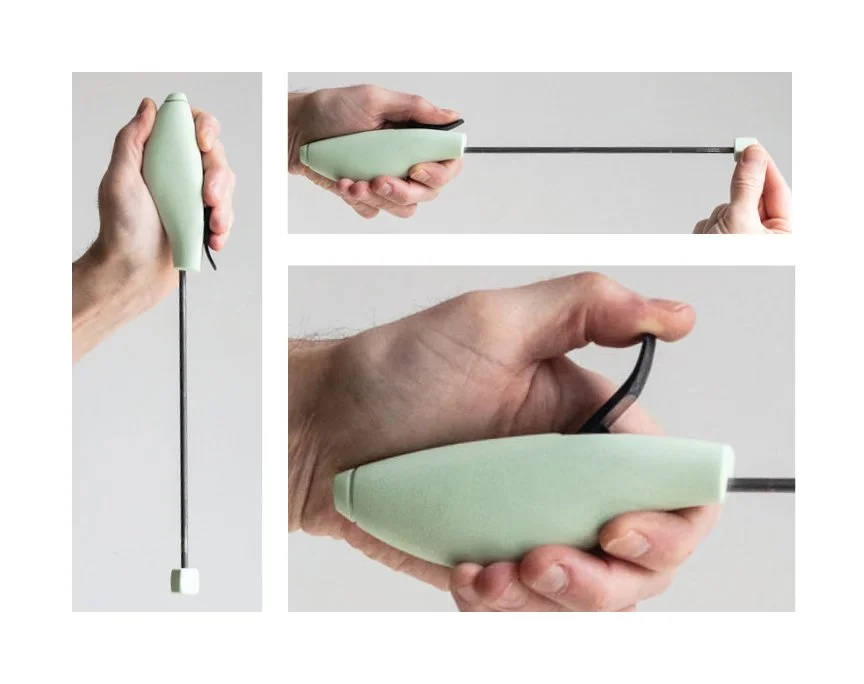

Concept Modeling

Here we’re converting 2-dimensional sketches into 3-dimensional conceptual models. These materials are easily shaped and durable enough for meaningful concept evaluation. Equally important, their manual fabrication enables the design team to evaluate critical components and features in real-time as they’re being made. As such, this type of modeling enables the design team to fail quickly and cheaply, discarding inferior concepts and focusing on the development of superior ideas. Modeling enables useful feedback with respect to form, proportion, interface layout, etc. better than sketches alone. Additionally, physical models serve as a valuable tool in helping the engineer efficiently construct CAD geometry.

Engineering: CAD Development & Prototype Modeling

By this stage of the project, the design team will have evaluated ideation sketches and conceptual models, which have been systematically evaluated to select the best design. The selected concept must now be more rigorously modeled in order to refine the design for testable prototypes. Using the physical concept models as a starting point, engineering generates CAD geometry that will serve to prototype the design - these proof-of-concept models will enable the design team to more critically evaluate the designs before engineering the product for fully functional and testable prototyping.

Concept Validation

Prototype User-Testing & Evaluation

User feedback can be valuable at various stages over the course of a project - to evaluate product aesthetics using concept sketches, or to test ergonomic viability using concept models. User testing can be critically important at this stage because of the advanced level of modeling. This is the first opportunity for user feedback with respect to performance - comfort, repeatable functionality, aesthetics, maintenance, storage, etc. By the end of this phase, focus group feedback will be compiled and evaluated, and will inform the design team as to which refinements may be required.

Engineering Refinement

Based on the user-testing prototype feedback, and considering design, engineering, and manufacturing criteria, final refinements will be made to the device’s CAD geometry. Additionally, final detailing will be performed during FEA (finite element analysis), tolerance analysis, and dimensioning part drawings. By the end of this phase, our client should be ready to engage a manufacturing partner for production of the device.

Design History File

Design History File

Regardless of the project’s scope and scale, Humanfactors generates and maintain a Design History File over the project duration. The DHF documents the project as it progresses, including product spec updates, all research materials, relevant meeting minutes and decision point strategies, concept evaluations, etc. This is a living, breathing document that helps to ensure project objectives and scheduling are being met, and that the development team’s expectations and goals are maintained as the project moves forward.

These materials can be tailored to seamlessly integrate within our clients’ QMS, be it ISO, CMMI, Six Sigma, or other Design Controls. In pursuing 510(k) clearance, here again we work with clients to focus documentation - from identifying design inputs to achieving design validation - so that the final technology transfer is optimized to submit.