First, identify the problem

Stryker Spine

AVS Navigator

The AVS Navigator instrument is an example of a project where Stryker’s Spine division relied on Humanfactors to evaluate an instrument already in production. In this case, we were called in to discuss dissatisfaction surgeons were experiencing. Was it the procedure? The instrument? The implant? Through conversation with surgeons, we helped define the problems—the instrument needed engineering and ergonomic refinement.

We started a very linear development process to refine an existing product—we began in the OR, studying procedures, and discussing instrument usage with everyone from surgeons to scrub techs. Detailed sketches explored concepts for easy implant attachment, positioning and deployment, ergonomic forms to provide line of sight, intuitive control, longterm comfort, and immediate user feedback. Foam models enabled a physical, full-scale user study of forms and features, helping the team quickly identify the most useful designs prior to CAD. Semi-functional SLA models let surgeons games-play with the operational and implant interface. And cut-steel, functional prototypes meant that the design team and surgeons could test the design against saw-bone and intensive cadaver labs. This was one of those projects where success lay not in some mysterious design process but in a diligent, conscientious march through pragmatic developmental activities.

Surgical Observation

To fully understand the scope of the design problem, we had to spend time in the OR - observing multiple surgeries, speaking with scrub techs, engaging surgeons about each procedural step. From the initial instrument-removal from cases and trays, to scrubbing down the instrument post-op, Humanfactors documented the entirety of the instruments’ use.

Market Research

An in depth investigation into similar instruments - with respect to handle design, mechanism function, interface and feedback - enabled Humanfactors to better understand how to differentiate this instrument’s features.

Industrial Design

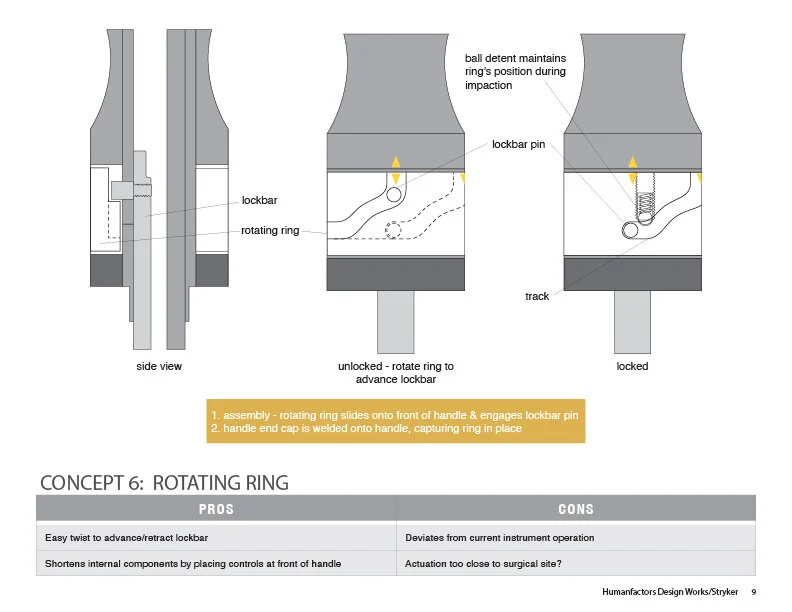

A series of concepts were developed to address the issues discovered during surgical observation. Features such as tactile feedback, interface placement, weight distribution, line of sight, and other critical design details were explored and evaluated.

Engineering

Concept exploration included engineering, where robust mechanisms were required to enable surgeons to reliably and repeatedly attach, adjust, and deploy the implant, all performed while fluid and bone fragments create an extrememely challenging environment.

Rapid Prototypes

Semifunctional prototypes were developed to enable multiple surgeons games-play with the instruments’ handles and interface. Group sessions allowed surgeons to challenge each other and compare procedural notes, all of which provided excellent user feedback.

Functional Prototypes

While models are critical in refining features like handle contours and the lock-knob’s texture, fully functional prototypes enable surgeons to evaluate the instrument during real-world operating scenarios. Cadaver labs were conducted to observe and document instrument performance and final surgeon feedback prior to finalizing the design.