More than just psychology—it's also knowing how to analyze, measure, and record the way products interact with the body

Human Factors Research

Understanding Anatomy

Humanfactors is more than just a name, it's also a large part of what we do. Understanding end users is more than just psychology—it's also knowing how to analyze, measure, and record the way products interact with different facets of anatomy. Humanfactors has studied specific diseases of the lung and directly incorporated that information into the design process. We have built 3D CAD faces to augment 3D scans of children to build fixtures for respiratory device research. We have generated simple yet innovative data sets to effectively present data that is accessible to everyone from engineering to marketing. We have adopted high speed photography to comparatively chart aerosol flows from MDIs to optimize device design.

Cadaver Geometry

Philips had obtained a cast-resin throat - useful geometry rendered useless in a block of resin. We rebuilt the geometry in CAD, and fabricated it in SLA for integration into an aerosol test fixture - this enabled us to observe and evaluate in real time the behavior of aerosols within human geometry and respiratory products.

Facial Analysis

Sleep apnea inserts, aerosol mask for children and adults, nebulizers - Humanfactors works on a broad scope of products whose ergonomics are dependent on our ability to understand facial geometry. Typically, simple comparative facial photography with thorough analysis is sufficient, but we’ve also worked with 3D scanning technology in order to understand, and in some case reproduce, facial geometry in order to effectively analyze the anatomy for which we’re designing.

Surgical Observation

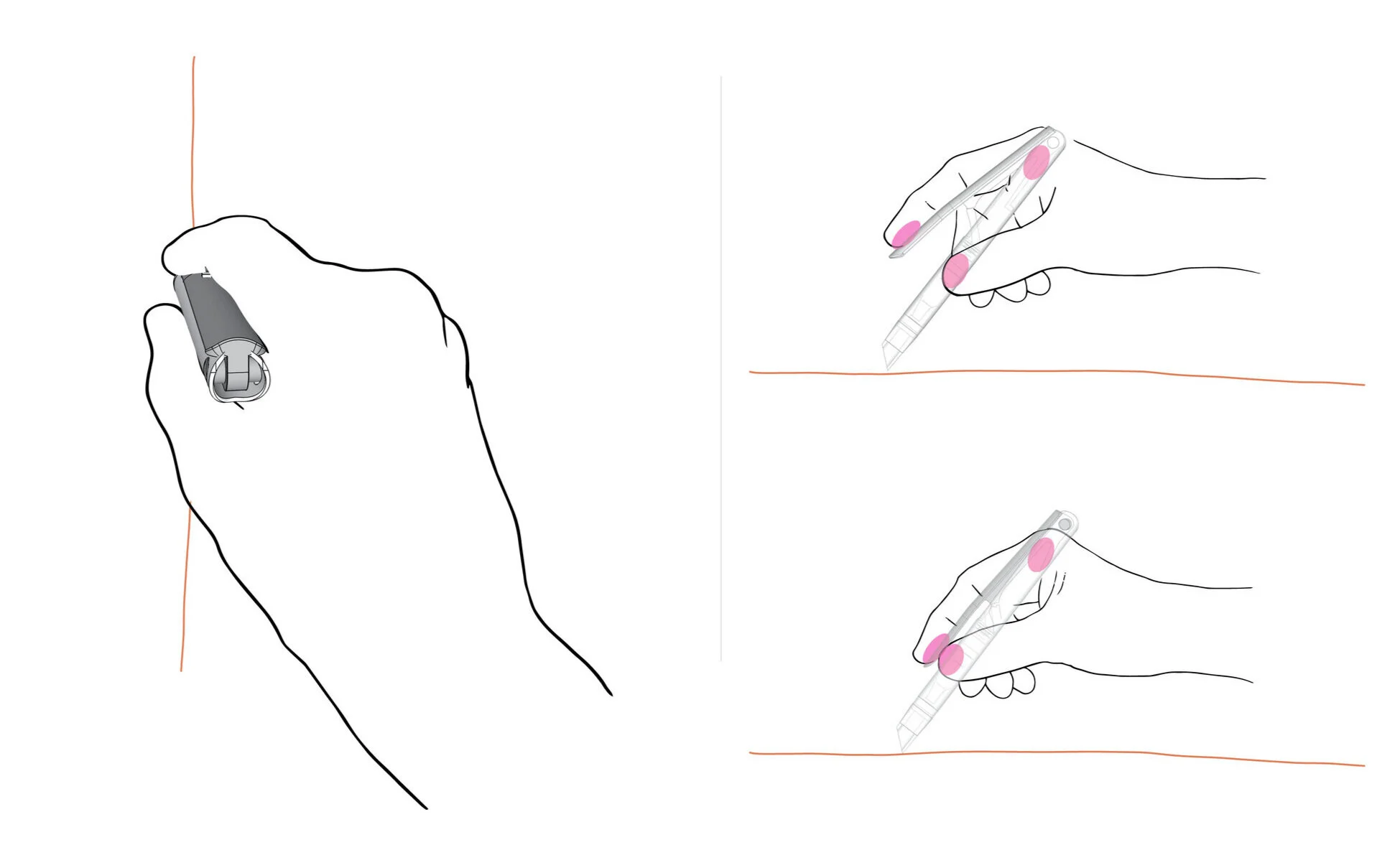

Surgical observation - passing & rasping. Surgical observation - impacting & releasing. Ergonomic design exploration through user scenarios based on surgical observation.

Ergonomic Modeling

Whether it’s foam, wood, or chewing gum and chicken wire, there is no more efficient means of determining whether or not a concept is worth pursuing than modeling. Between sketch ideation and CAD, this rapid modeling enables the team to fail quickly and cheaply - any qualified designer ought to be able to produce half a dozen models of the instrument below in the amount of time it would take to develop in CAD and 3D print the result. There is also the realtime feedback while fabricating these models that inform and refine on the fly.

Ergonomic Analysis

And once models are made, carefully analyzing how the design works with the user is imperative to the product’s success. Understanding how an object feels in the hand - is it prone to slipping, are there pinch points, how much pressure is required for actuation - requires careful observation and attention to detail.